Description ZOGPI has design and manufacturing teams in various fields such as: mechanic, electronic, magnet, software for design and manufacture different types of intelligent pigs in IRAN. All of mechanical and electronic analyses and tests are done in ZOGPI to earn the best results.

In-line Inspection (ILI) ; involves the evaluation of pipes and pipelines using “smart pigs” (both tethered and non-tethered) that utilize non-destructive examination techniques to detect and size internal damage. ILI measures and records irregularities in pipelines including corrosion, cracks, deformations, or other defects.

ILI is a common practice throughout the oil and gas industry and has proven invaluable for examining extensive pipelines. It makes inspecting the condition of long stretches of pipelines, a task that used to be incredibly expensive and time consuming, far more easy and economical.

There are several different types of smart pigs utilized in ILI activities, each with its own set of advantages and disadvantages. Some are more effective at detecting certain types of corrosion or damage in different types of pipes, depending on their NDE capabilities.

Magnetic inspection ; of in-line inspection is based on registering stray magnetic fields, arising from magnetization of the wall of the pipeline. The essence of this method is that if there is any anomaly in the wall of the pipeline, a part of magnetic flow is dispersed on the anomaly, and this may be recorded by the sensor, located close to the pipeline surface.

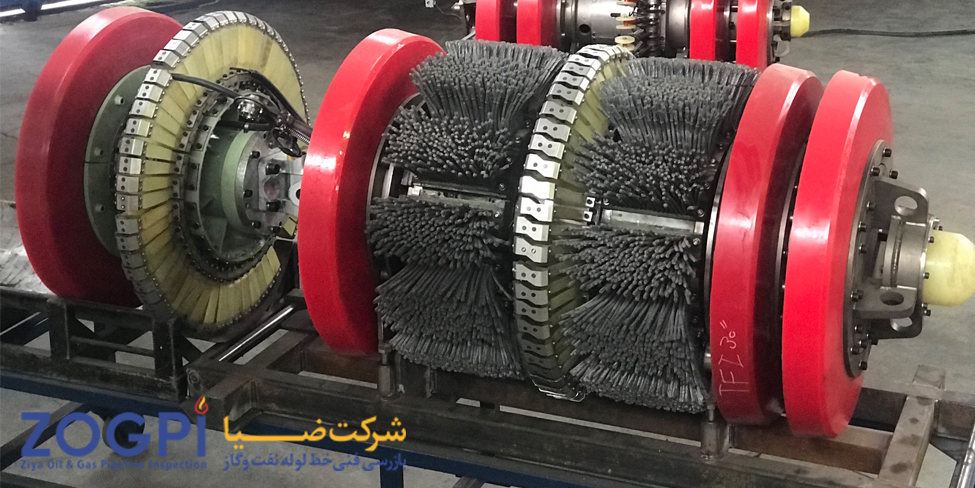

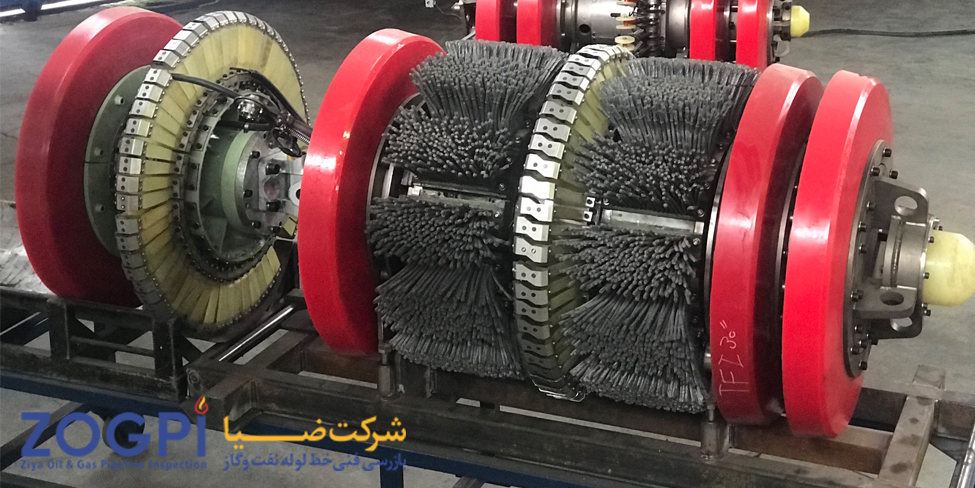

Magnetizing the wall of the pipeline by ILI tools is provided through permanent magnets, placed on a cylindrical yoke, and through flexible metallic brushes, transferring magnetic flow from the magnets to the wall of the pipeline. Magnetic inspection has the following advantages:

- high sensitivity to metal loss features

- high stability of monitoring results

- visibility of monitoring results

- high security and producibility of construction of ILI tools

Magnetic inspection is executed by a complex of ILI tools with a diameter from 8” to 56” including: - Magnetic Flux Leakage (MFL)

- Transverse Field Inspection (TFI)

MFL - Magnetic flux leakage tools are designed to detect and record:

- corrosion anomalies (corrosion, pitting, pinhole, circumferential grooving)

- artificial defects of circumferential positioning

- circumferential metallurgical anomalies

- circumferential stress-corrosion cracks

- girth weld anomalies

Magnetic flux leakage tools of high resolution (MFL) are utilized to record and detect the signals of longitudinal magnetic flow leakage at anomalies location on the pipeline wall.

TFI-Transverse field inspection tools (TFI) are designed to detect and record:

- corrosion anomalies

- artificial defects of axial positioning

- axial metallurgical anomalies

- axial stress-corrosion cracks

- seam weld anomalies

A unique construction of magnetizing system of Transverse field inspection tool (TFI) enables to achieve (most) high accuracy in detecting axially-positioned cracks, which are the most dangerous anomalies of trunk pipelines.