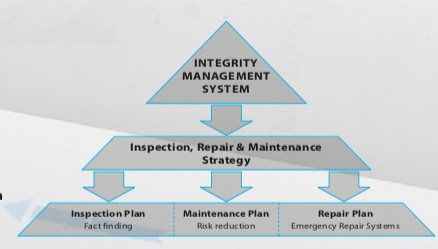

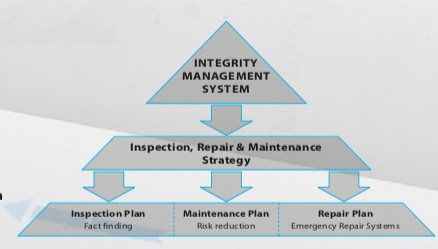

Integrity Management System

Description When a pipeline is run to failure, flow of product becomes increasingly inefficient and the number of unplanned repairs escalates. More unplanned repairs means higher costs, and revenues lost through downtime.

In an emergency, simply having kit on standby might sometimes be better than doing nothing, but the kit must be accompanied by a well thought out plan. Otherwise the result is serious damage to reputation and bottom line.

We ensure that operators experience the least overall downtime during steady state operations, and they achieve earliest possible re-commissioning during an unplanned repair. We do this by helping them integrate emergency preparedness with their ongoing operations in the most straightforward way possible. As specialists in planning the repair and maintenance of complex pipeline systems we translate plans into action. Whether it is conducting piggability studies, or designing cleaning runs for In-Line Inspection or throughput optimization, our highlyexperienced marine, pipeline and intervention specialists ensure that plans are inherently practical, whilst adhering to the toughest technical standards. Once preparations are completed, we supervise the contractors – making sure that the probability of error is absolutely minimized.

- Risk assessment and failure mode analysis.

- Maintenance and repair strategy development and workplanning.

- Emergency Pipeline Repair System (EPRS) : contingency planning , and unplanned repair procedure development.

- Inspection planning and feasibility studies.

- NDT feasibility studies , method selection , and procedure development

- Fitness for Purpose analysis , reporting , and mitigation action design.

- Corrosion prevention consulting

- Chemical cleaning advisory services

- Pipeline (and tank) integrity management software development and consulting