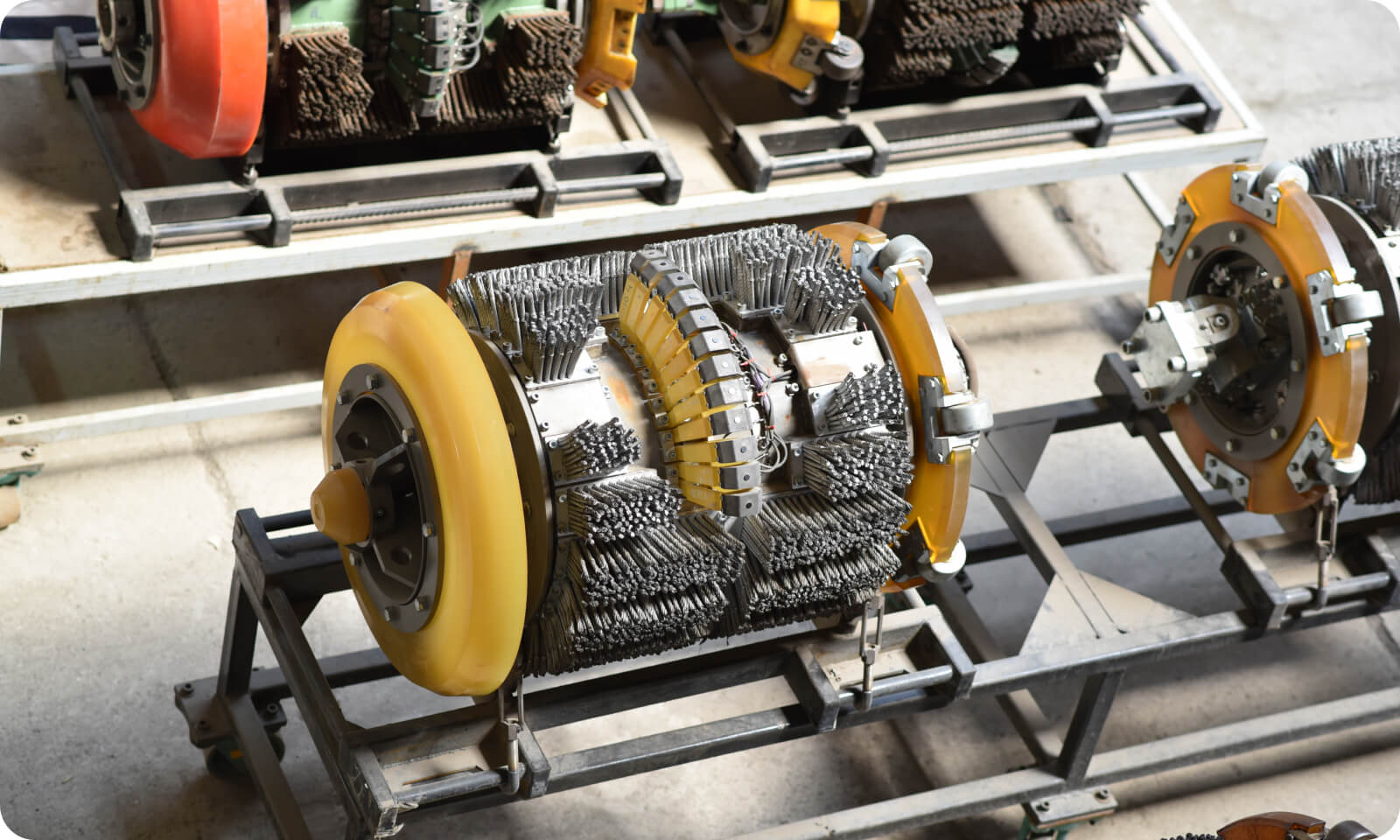

🔍 1. Magnetic Flux Leakage (MFL)

✅ Best for detecting corrosion, metal loss, and pitting defects.

📌 Common choice for high-pressure transmission gas lines due to its robustness and reliability.

🔍 2. Inertial Measurement Unit (IMU) with XYZ Mapping

✅ Provides accurate geospatial data for pipeline route, bends, and depth of cover.

📌 Often combined with MFL or caliper tools to support integrity assessments.

🔍 3. Caliper Inspection

✅ Ideal for identifying deformations, dents, and ovalities.

📌 Used as a preliminary inspection or to validate pipeline geometry before high-resolution ILI.

🔍 4. Ultrasonic Testing (UT)

⚠️ Requires liquid couplant, so it's less suitable for gas pipelines unless the line is temporarily filled with liquid (liquid batching).

📌 Excellent for wall thickness measurement when applicable.

🔍 5. EMAT (Electromagnetic Acoustic Transducer)

✅ No need for a liquid couplant.

📌 Suitable for detecting cracks, especially stress corrosion cracking (SCC) in dry gas lines.

✅ Choosing the Right Toolset:

The best approach often involves combining multiple tools, such as MFL + IMU + Caliper, to gain a comprehensive view of pipeline condition.

Proper inspection ensures:

✅ Best for detecting corrosion, metal loss, and pitting defects.

📌 Common choice for high-pressure transmission gas lines due to its robustness and reliability.

🔍 2. Inertial Measurement Unit (IMU) with XYZ Mapping

✅ Provides accurate geospatial data for pipeline route, bends, and depth of cover.

📌 Often combined with MFL or caliper tools to support integrity assessments.

🔍 3. Caliper Inspection

✅ Ideal for identifying deformations, dents, and ovalities.

📌 Used as a preliminary inspection or to validate pipeline geometry before high-resolution ILI.

🔍 4. Ultrasonic Testing (UT)

⚠️ Requires liquid couplant, so it's less suitable for gas pipelines unless the line is temporarily filled with liquid (liquid batching).

📌 Excellent for wall thickness measurement when applicable.

🔍 5. EMAT (Electromagnetic Acoustic Transducer)

✅ No need for a liquid couplant.

📌 Suitable for detecting cracks, especially stress corrosion cracking (SCC) in dry gas lines.

✅ Choosing the Right Toolset:

The best approach often involves combining multiple tools, such as MFL + IMU + Caliper, to gain a comprehensive view of pipeline condition.

Proper inspection ensures:

- Early detection of critical defects

- Compliance with integrity regulations

- Cost-effective maintenance planning